Maximize Airflow: A Comprehensive Guide to Fan Maintenance

|

|

Time to read 4 min

You are being redirected to QC Supply Pharmacy, where you’ll find a wide selection of high-quality prescription and pharmaceutical products for animals of all sizes.

Enjoy the same great service and expertise you trust from QC Supply.

Click below to continue shopping.

Continue

No thanks, stay on the main site

Powered by

You are being redirected to QC Supply Pharmacy, where you’ll find a wide selection of high-quality prescription and pharmaceutical products for animals of all sizes.

Enjoy the same great service and expertise you trust from QC Supply.

Click below to continue shopping.

Continue

No thanks, stay on the main site

Powered by

|

|

Time to read 4 min

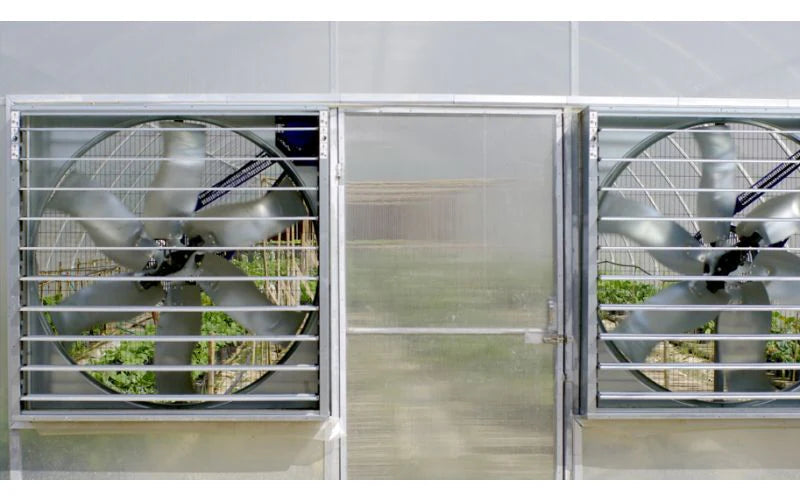

With warm weather on the way, now is the time to perform a check on all your fans and perform any necessary maintenance. Well-working exhaust and ventilation fans are necessary for maximum fan performance, healthy air quality that will help keep your livestock vigorous and productive. Over time, your fans are subjected to significant wear and tear—like any machine with moving parts. To help reduce the need for costly future equipment replacement and downtime, develop the habit of regularly checking and maintaining your fans.

Putting together a maintenance checklist can be a great way to keep an eye on major and minor problem spots. Maintaining a checklist can also help you avoid the need to “reinvent the wheel” each spring—you’ll already have your list of necessary things to inspect and it will save time.

A model fan maintenance checklist might look something like this:

After a while you will know which parts are likely to wear out first. Keeping a stock of spare parts is a smart thing to do, especially if you’re able to perform basic spot-repairs yourself. Bearings, belts, and pulleys are cheap and don’t take up a lot of space. If you tend to need a specific part or two on a regular basis, building and maintaining a good relationship with your supplier can also be a smart move.

A safe bet is to grease twice a year but your manufacturer may have other ideas. Be sure to follow manufacturer recommendations, if any. If you do have recommendations but do not follow them, you may be voiding parts of your warranty. Some devices will even track operation hours electronically which can help you keep an accurate maintenance schedule.

It might not look like much, but dirt and dust are an added obstruction to your fan and reduces your airflow speed. This means your fans have to work harder and you sacrifice airflow and efficiency. Over time, they will become increasingly inefficient by as much as 30%. To avoid this, a regular spot cleaning is a good practice and then a big cleaning at the end of warm weather when you shut them down for winter. You can use a pressure washer or air compressor to clean fan housings, guards, shutters, and louvers, but make sure to keep all electrical components covered up.

Improperly tensioned and/or worn fan belts are a common cause of poor performance. Belts transfer power, so slack or worn belts will lead to inefficiency. Loose belts will reduce gear ratios resulting in loss of airflow and a shortened belt life. Worn belts, on the other hand, will ride lower in the pulleys and also affect the performance of the fan.

If the pulleys are out of alignment they can wear your belts out quickly, much like tires on a car—if they’re out of alignment, you’ll get uneven wear and have to buy new tires long before you should need them. Check your pulleys for wear, too. Worn pulleys will also cause belts to sit lower and reduce fan performance.

Your motor is the heart of your fan. You’ll want to make sure the draw is correct. If the motor is drawing too many amps, you likely have a problem elsewhere making the motor work harder than it should. Belt tension and built-up dirt on impellers, fan blades, and in the housing can be the culprit. If those seem to be as they should but the motor still is not functioning correctly, you may be due for a new motor.

If you are geared for repairs, you can do a lot with a few tools.

Keeping your fans running efficiently will be central to providing your livestock with fresh, healthy air. In turn, they will be healthy producers for you through the warm months and years beyond.

Did we forget any important details? Let us know in the comments section and then check out our wide array of fans, parts, and tools—everything you’ll need to stay cool!